Working with Designers & Engineers to attain the best possible 3D Design

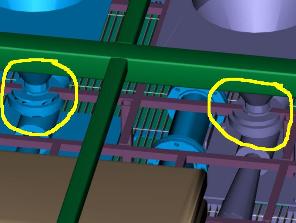

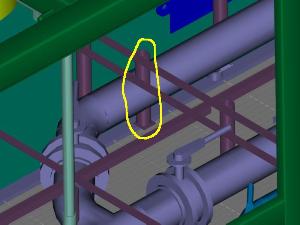

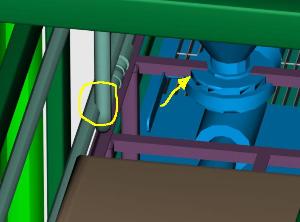

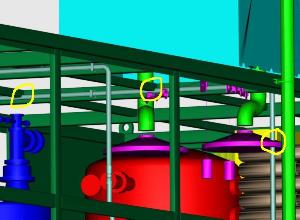

Examples of Really BAD Design even in 3D!

I hesitated to add these pictures but decided I would as they illustrate an important point.

These pictures were received from a manufacture that is primarily a 2D design facility with

one contract person designing in 3D. There are eight (8) very prominent interferences in

the below pictures and all of this is within a 15’ x 15’ area. These pictures illustrate two

things: 1) poor design capability and 2) a near total lack of checking one's work. When I

received this 3D model I was told it was "AS-BUILT" which makes it all the more terrible.

This is the reason you want to use an experienced company to do your 3D design work.

Make sure they check their design work as it progresses. Besides checking the

engineering personnel you should check the CAD personnel. They will be producing the

final drawings and your product will be built from those drawings.

| |

Angle runs through both discharge valves.

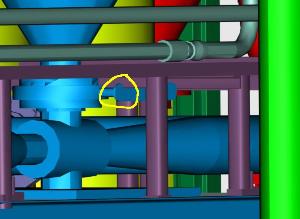

Handle on valve into support tube steel.

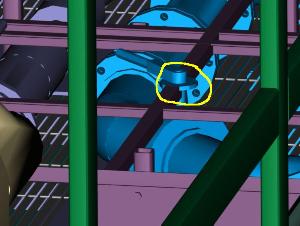

Another valve handle into tube steel.

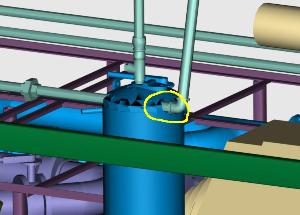

Pipe runs directly through tank.

Tube steel runs through 8" pipe.

Pipe through another pipe and previous hit.

Amazingly 1 pipe hits 3 different objects.